Introduction to High Entropy Alloys

Professor Jien-Wei Yeh first proposed the concept of high-entropy alloys (HEAs) in 1995, challenging the traditional view that alloys are based on a single primary metal. HEAs utilize multiple principal elements (≥5) with atomic percentages between 5%–35%, leveraging the high-entropy effect to form stable, innovative alloy systems.

These alloys exhibit superior hardness, high-temperature resistance, wear and corrosion resistance, as well as non-toxicity and cost-effectiveness. Their versatility makes them ideal for applications, such as in smart machinery, green energy, and national defense.

Four core effects

Compared with traditional alloys, high entropy alloys have four core academic effects: high entropy effect in thermodynamics, severe lattice distortion effect in crystallography, slow diffusion effect in kinetics, and cocktail effect of mechanical, physical, and chemical properties. Therefore, high entropy alloys can surpass traditional known alloy materials in properties.

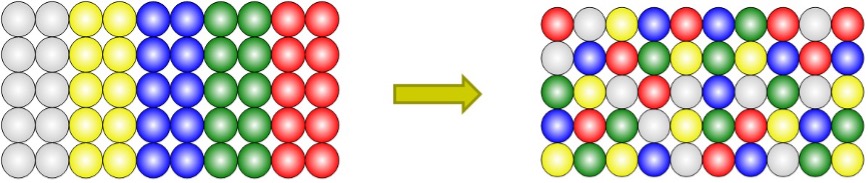

Since the composition disorder and entropy of high entropy alloys are higher than those of traditional materials, the mixing of elements can be promoted, so it is easy to form a simplified structure (BCC/FCC) or amorphous, thereby producing a stable solid solution phase and inhibiting the formation of brittle intermetallic compounds.

The lattice structure of a high entropy alloy contains atoms of multiple elements arranged in a lattice. The strain in the crystal lattice is caused by the different atomic sizes of the various elements and the differences in the bondings between the elements. These lattice strains will cause the lattice to raise its energy state and affect many properties of the material, such as increasing hardness and strength, and decreasing electrical and thermal conductivity.

The sluggish diffusion effect in high-entropy alloys slows atomic movement due to lattice distortion, as atoms diffuse via vacancy mechanisms with increased activation energy. The overall diffusion rate is limited by the slowest-moving element, enhancing thermal stability, grain growth resistance, and microstructure control—key benefits for high-temperature applications and mechanical property optimization.

High entropy alloys are alloys with multiple main elements. They not only present the basic characteristics of all atoms themselves, but also the composite effects produced by the interactions between atoms, thus achieving an effect similar to that of composite materials, making the properties and applications of the alloys more diverse. For example: adding light elements to high-entropy alloys will reduce the overall density of the high-entropy alloys; adding oxidation-resistant elements such as Al, Cr, and Si will improve the oxidation resistance of high-entropy alloys.

Service Applications

World-leading capabilities in high-entropy alloy design

The high-entropy team has accumulated more than 30 years of high-entropy alloy research and has the most extensive database and experience in the world. It can design high-performance high-entropy alloys that traditional alloys cannot achieve based on special performance requirements.

Advanced high-entropy alloy manufacturing technology

Compared with traditional alloys, the manufacturing technology of high-entropy alloys is different, but the high-entropy team has accumulated decades of experience and has mastered many high-entropy alloy related technologies such as atmospheric melting, arc melting, vacuum induction, magnetic levitation melting, casting, rolling, forging, heat treatment, as well as testing and analysis capabilities.

Outstanding high entropy alloy and technology development capabilities

The high-entropy team has a deep understanding of high-entropy alloys, and together with the joint efforts of many partners, has developed many outstanding products, such as ultra-wear-resistant machine tool indexing worm gears, high-hardness beryllium-free and non-toxic spark-free safety tools, and ultra-high elastic high-entropy alloy plates.