Wear-resistant entropy alloy

EM-12501

The wear-resistant entropy alloy EM-12501 is a Be-free, Pb-free, non-toxic, high-strength copper-rich alloy with a high hardness of HV200 and excellent properties such as high wear resistance, high corrosion resistance, and high oxidation resistance. Applied to gear bushing wear-resistant parts, the unique beryllium-free and lead-free patented formula will not cause harm or pollution to operators and the environment like lead-containing or beryllium-containing on copper alloys. EM-12501 is a new generation alloy that is in line with our sustainable business philosophy.

Material Features

The wear-resistant entropy alloy EM-12501 is a Be-free, Pb-free, non-toxic, high-strength copper-rich alloy with a high hardness of HV200 and excellent properties such as high wear resistance, high corrosion resistance, and high oxidation resistance. Applied to gear bushing wear-resistant parts, the unique beryllium-free and lead-free patented formula will not cause harm or pollution to operators and the environment like lead-containing beryllium-containing copper alloys. EM-12501 is a new generation alloy that is in line with our sustainable business philosophy.

| High wear-resistant specimen material | Adhesive wear resistance (m/mm³) |

|---|---|

| EM-12501 | 17307 |

| Aluminum bronze (ALBC3) | 3360 |

| Brass (C26000) | 3956 |

Note: The wear test adopts the pin-on-disc adhesive wear test method. The grinding disc material is SKD61. The test conditions are immersed in lubricating oil, the load is 5 kg, and the wear distance is 5400 m.

RoHS 2.0 limits the toxic lead content of general materials to less than 0.1%. The Department of Health and Human Services (DHHS), Environmental Protection Agency (EPA) and International Agency for Research on Cancer (IARC) have determined that lead is a carcinogen. Exposure to a high-lead environment will cause anemia, weakness, and damage to the liver and brain. Higher levels can cause death. Since lead slag, lead vapor, and lead dust produced during refining, melting and casting, heat treatment, machining, and grinding processes are harmful to health and the environment, the use of lead-containing copper alloy products is equivalent to contributing to the lead pollution disaster in the upstream, midstream and downstream. Such use will affect the conscience of a company. Although RoHS has extended the exemption for high-lead copper alloy C36000 (Cu-Zn-Pb) for machinery on July 1, 2021, it does not mean that the use of lead-containing products is justified. If lead-free copper alloy products are available on the market and meet the required functions, conscientious companies should be the first to use lead-free products. The current ban on lead-containing products in hardware and solder is a reflection of this trend. Therefore, the wear-resistant entropy alloy EM-12501 containing no lead at all is a revolutionary high-performance material that complies with the world’s environmental protection requirements.

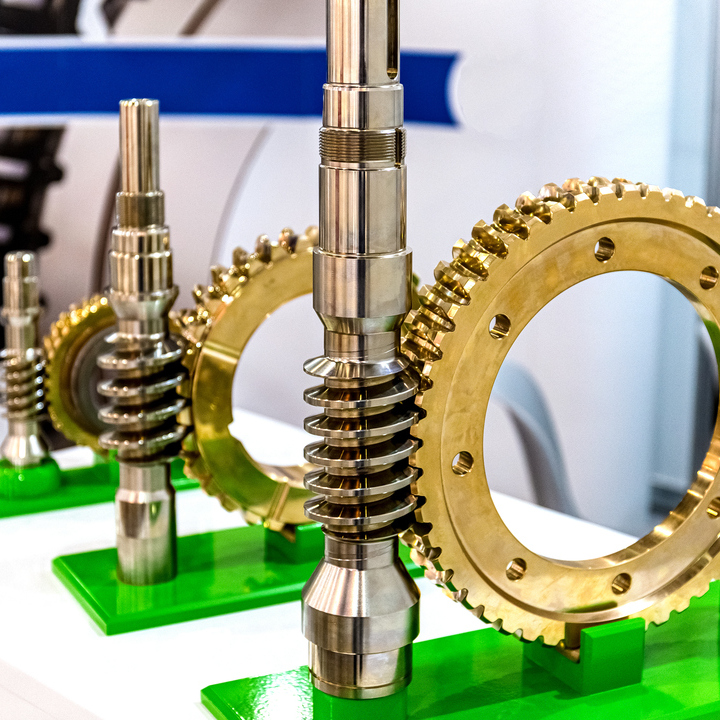

Entropy alloy EM-12501 can be made into worm gears for use in the indexing plates of fourth-axis and fifth-axis CNC machining center’s. The teeth are wear-resistant and have a long service life, which greatly reduces the need for downtime adjustment and backlash, thereby improving the precision of the machined parts and the production rate.

Entropy alloy worm gear for machining center’s indexing plate