Heat-resistant entropy alloy

EM-400

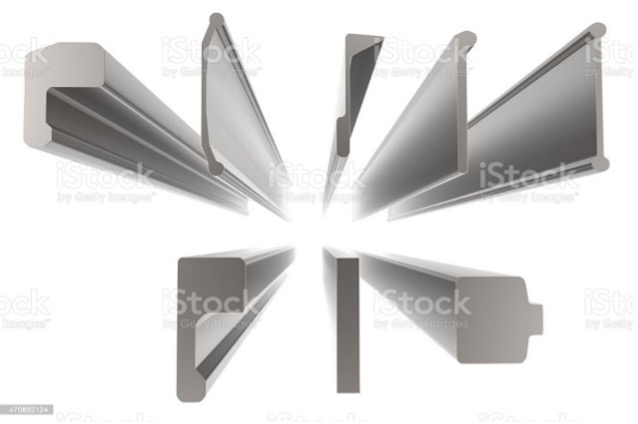

The EM-400 series is a heat-resistant entropy alloy with exceptional high-temperature hardness, maintaining over HV200 at 900°C. It offers excellent resistance to heat, wear, and corrosion, making it ideal for hot-working tools, high-temperature components, and equipment. Its patented formula can replace SKD61 die steel in applications such as extrusion dies, molds, and rollers. EM-400 represents a disruptive innovation that enhances industrial autonomy.

Material Features

The EM-400 series of high entropy alloys is a patented formula developed using the latest high entropy alloy concepts. It has a hardness greater than HV400 at room temperature and a hardness greater than HV200 at 900 degrees Celsius. The high temperature load bending test video is shown below, which shows that EM400 has better performance than the nickel-based superalloy Inconel 718:

Note: High temperature load bending test, the left side is the heat-resistant entropy alloy EM-400 round bar, the right side is the nickel-based superalloy Inconel 718 round bar, the total length of the round bar is 20 cm, the diameter is 3 mm, the load is 300 grams, and the flame jet in the middle reaches is about 1000 °C.

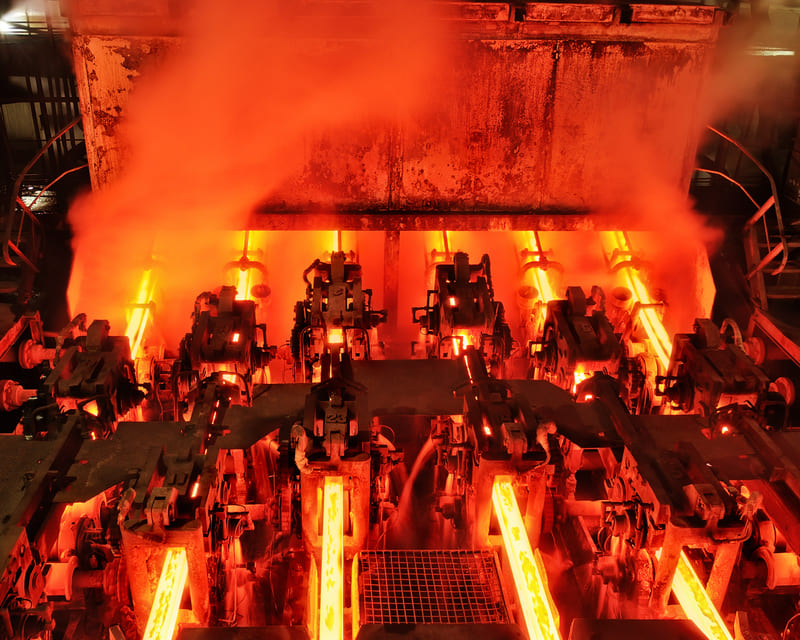

The heat-resistant entropy alloy EM-400 series can be used in hot working tools and molds, high-temperature application components and high-temperature application equipment.

Used for extruding high melting point metal profiles